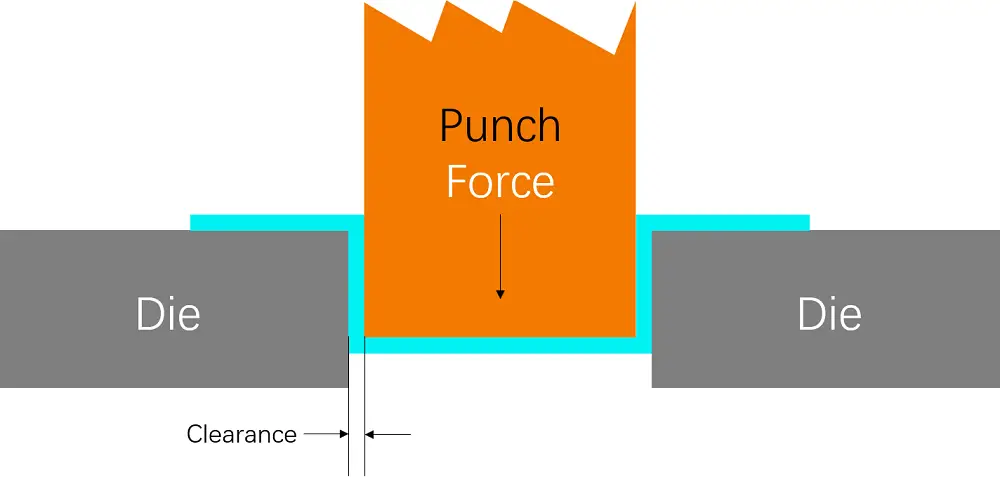

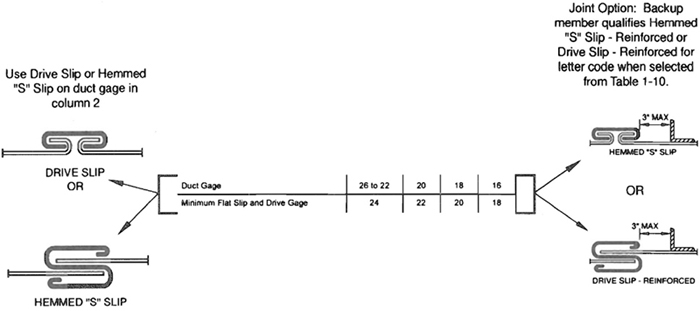

16 6 as sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

As sheet metal stock thickness increases the clearance between.

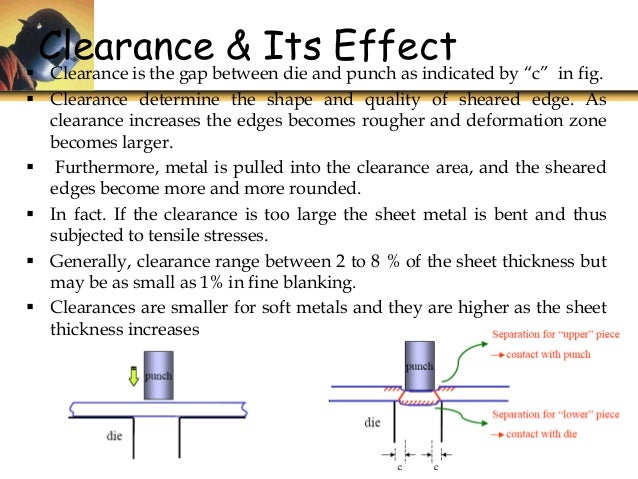

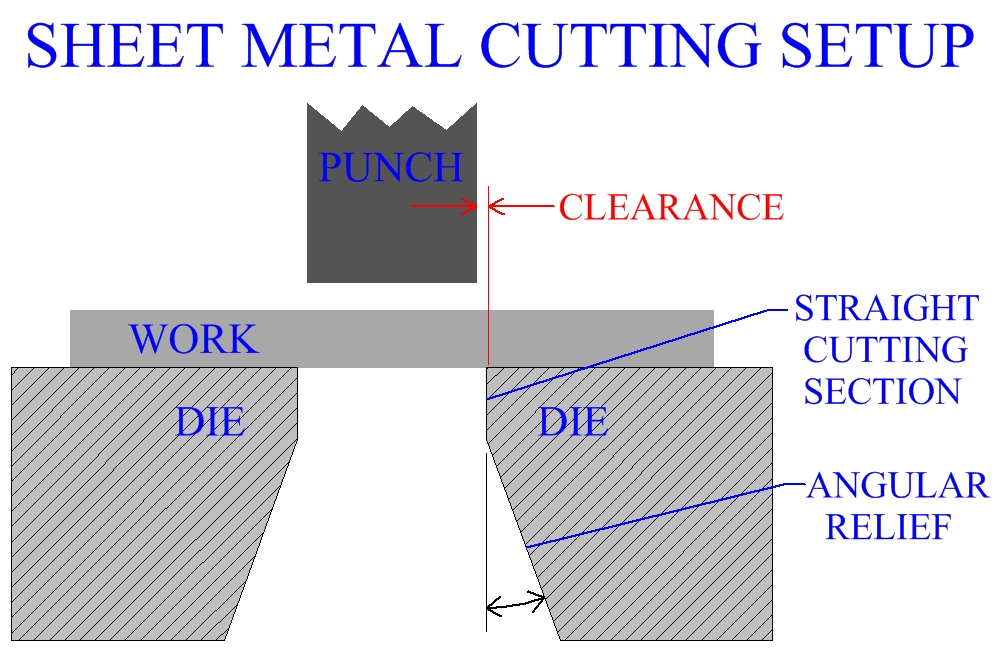

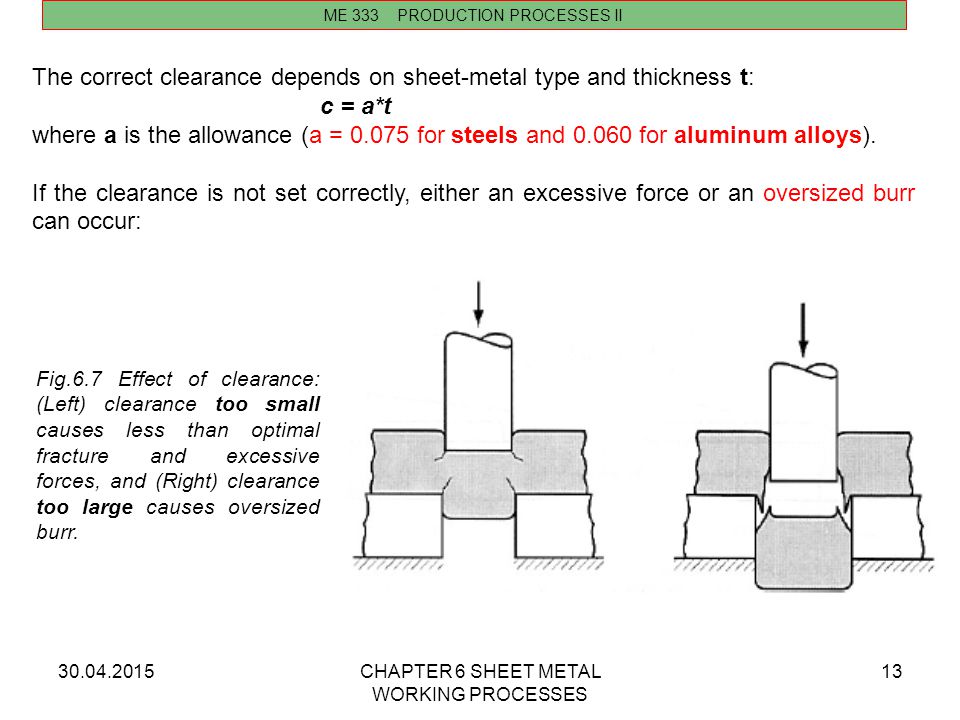

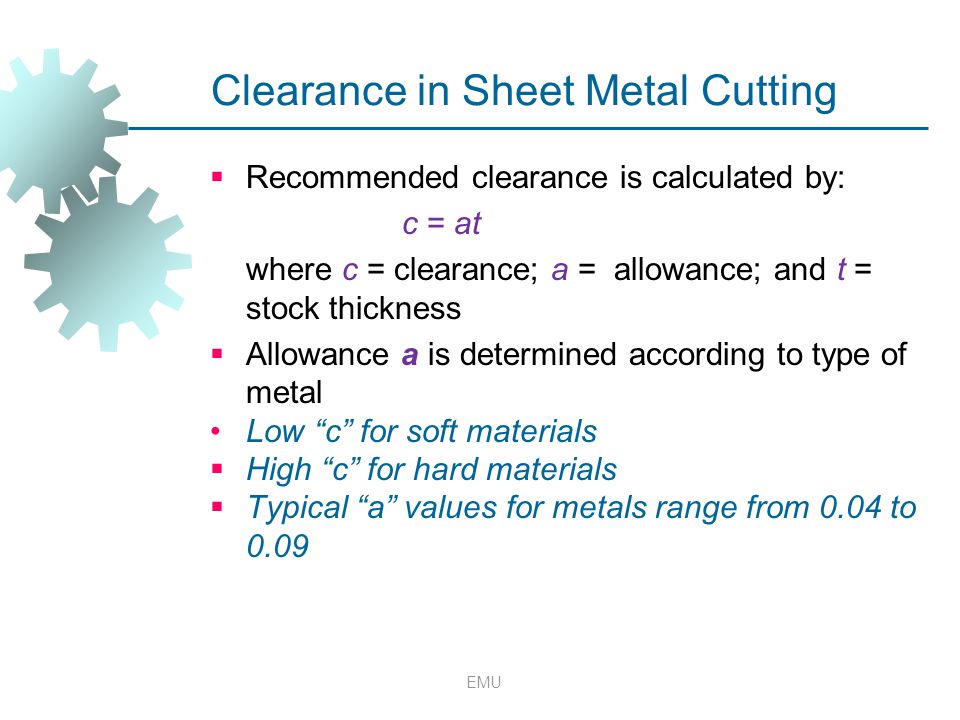

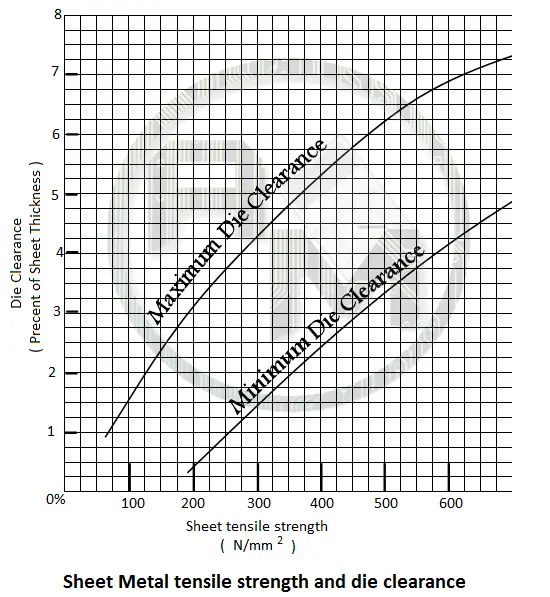

The greater the sheet metal thickness the higher the clearance value should be.

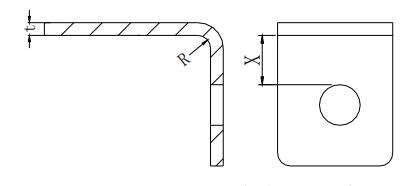

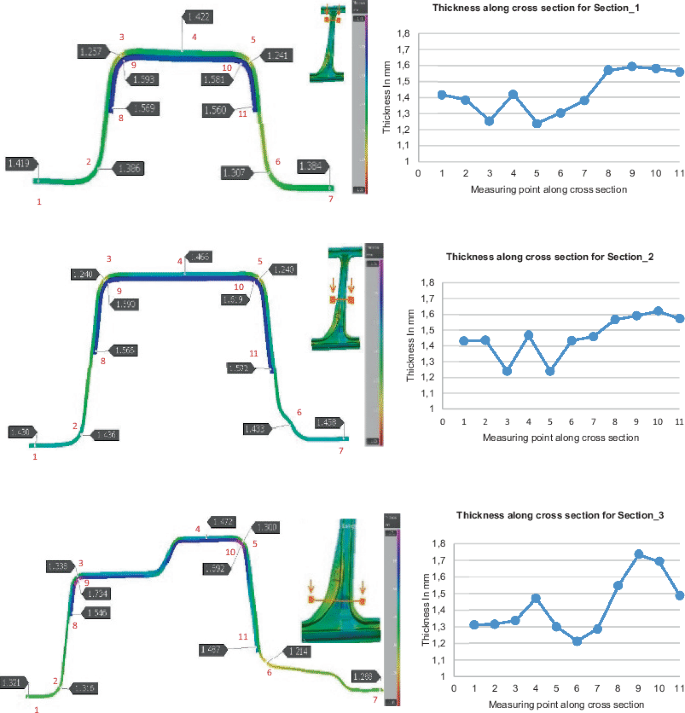

Because sheet metal parts are manufactured from a single sheet of metal the part must maintain a uniform wall thickness.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be.

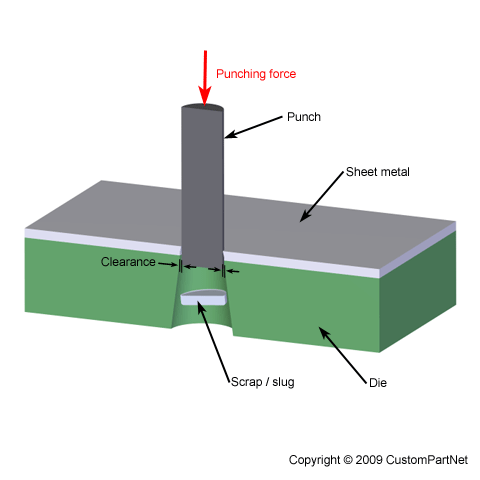

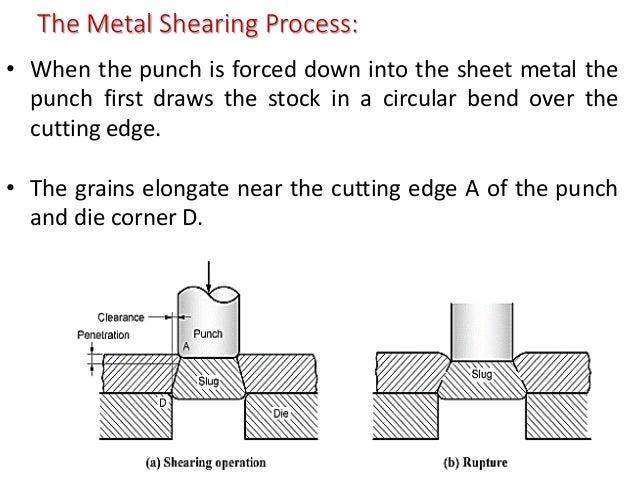

B a circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

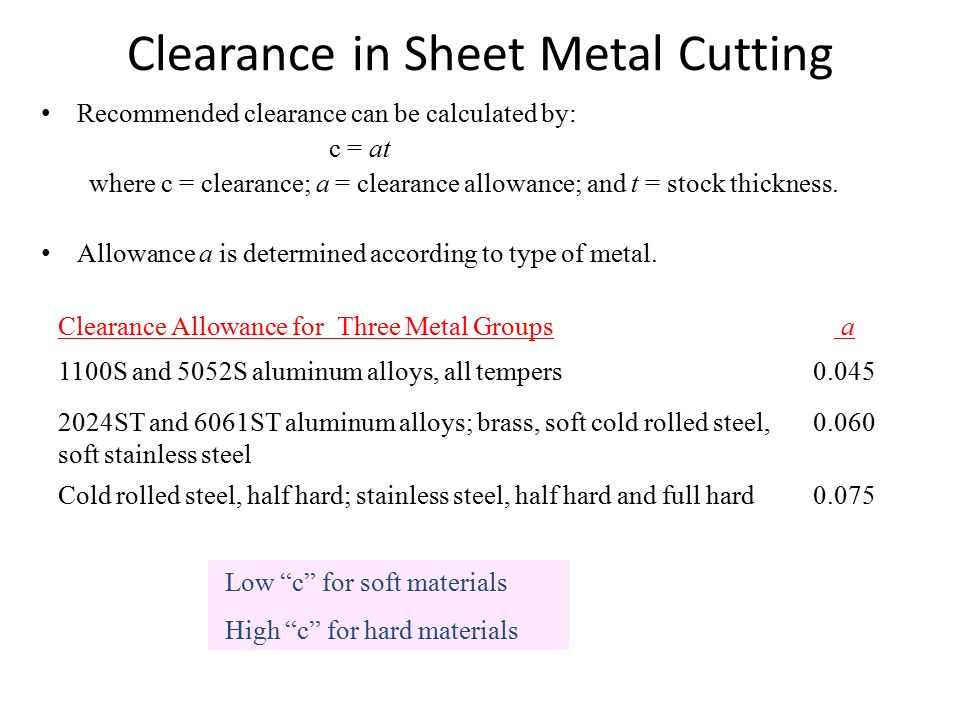

A large factor is the type of work material and its temper.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

Can make the shear crack joint balanced blanking force good punching quality long service life of the mold.

In manufacturing industry there is a range of optimum values for specific processes clearances may span from 1 to 30 of sheet thickness.

Recommended punch and die clearance table see table 1 below the harm of too small clearance.

Generally typical values span from 3 to 8 of sheet thickness.

A be decreased b be increased or c be unaffected.

The optimum clearance between the punch and die.

A circular sheet metal slug produced in a hole punching operation will have the same diameter as the.

The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

The life of the mold is shortened.

The md building products 36 in.

The sheet features a union jack style perforated design.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet.

As sheet metal stock hardness increases the clearance between punch and die should.

The punching force increases.

Increased 16 7 a circular sheet metal slug produced in a hole punching operation will have the same diameter as the a die opening or b punch.

X 36 the md building products 36 in.