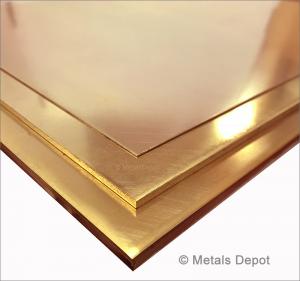

Often called free machining and free cutting brass it stands up to high speed drilling milling and tapping operations with minimal wear on your tools.

Attaching pieces of brass metal sheet.

It s commonly used for gears pinions and lock components.

Still it s hard to beat the speed of applying a strip of tape to a part.

It requires no screws rivets or other pieces of fastening hardware.

K s percision metals 16405 brass sheet metal rack 0 025 thickness x 6 width x 12 length 22 gauge 3 pcs per car made in usa by k s 10 39 10.

Metals depot america s metal superstore is your complete supplier for industrial metals worldwide.

Item 168753 model 11786.

There are few limitations on fastening tabs.

The glue most suited for gluing brass to surfaces is 2 part epoxy polyepoxide.

Leave parts undisturbed as the bond forms.

As for all metals you ll need a brand of glue that creates a chemical bond in order to glue pieces of brass together.

The metal tabs that are to be bent should be between 0 12 and 0 8 in.

Brass is a metal.

The technique of joining metal pieces is as simple as applying the glue to the surface of the metal where it needs to be joined from pressing the metals together and letting it dry in most cases the pieces to be glued have to be under pressure after clue is applied until it is dry.

Metal epoxies have longer curing times and often require clamping for up to 60 minutes.

39 16 46 16.

Many epoxy metal glues require mixing adhesive and hardener components then applying with a specialized tool.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.

Using an adhesive for metal to metal assemblies can reduce or eliminate many of these troublesome issues although bonding metal to metal does require surface preparation which could potentially add a step to your manufacturing process.

Which glue is best.

When you need to glue brass be sure not to choose a glue that is brittle or that expands.

There are many.